The ingredients from my ingredient shopping arrived really quickly – I placed the order on Thursday at 17:30 and they arrived on Saturday. Impressive work from The Homebrew Company!

I put together the workflow below and printed it out so I’d have something to follow along with on brew day. It really helped pinpoint things to focus on and times when I’d be able to prepare the next step while waiting for target temperatures.

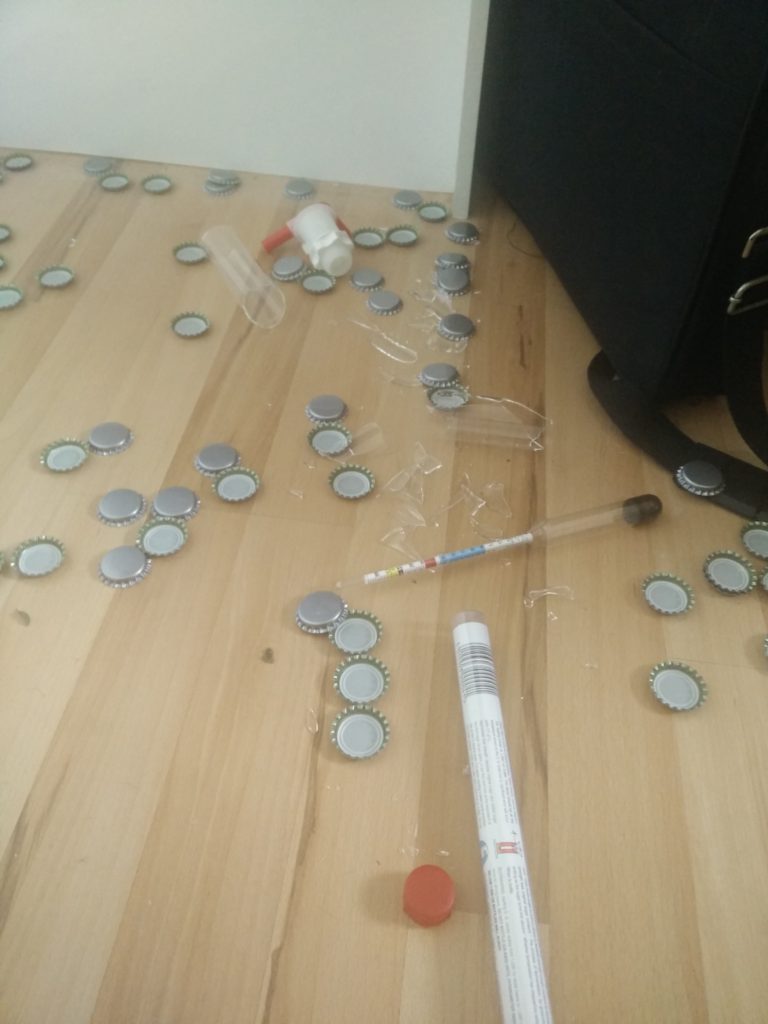

I had a setback in preparing for brew day, however, as I managed to drop my hydrometer and sample tube – the only two glass pieces of brewing paraphenalia! Needless to say, both of them shattered. Thankfully, I was able to borrow a hydrometer off my friend Diarmaid. I used a tall pint glass as a sample tube, but ended up having a lot of wasted liquid while doing so, I’ll have to be conservative about checking my specific gravity until I source a new one.

I tweaked the recipe slightly according to the style guidance from Brewer’s Friend, which should hopefully compensate for my extra dark barley.

A bad thing happened

Other than that, the brew went off without a hitch! Looking forward to the taste test already!

Brew Workflow:

Day before brew

Test hose and chiller attachment

Clean with standard detergent:

kettle

kettle element

kettle tap

chiller

stirring paddle

thermometer

fermenter

fermenter tap

airlock

Borrow hydrometer to replace broken one!

Brew Day

Steeping Specialty Grains

Bring 2L of water to 67 degrees Celsius

Weigh and put specialty grains in straining bag while waiting

Steep specialty grains for 30 mins in 67 degree water

10 minutes from end of steeping, bring another 2L of water to 80 degrees

Add water from steeped grains to kettle

Put straining bag in colander

Pour 80 degree water through colander to add grain washings to kettle

Weigh ingredients

Caramel Crystal Malt 82 EBC – 160g

Caramel Crystal Malt 240 EBC – 160g

Roasted Barley 800 EBC – 100g

Hops East Kent Goldings – 35g

Seal unused grain and hops in plastic food bags & store hops in freezer

Adding to the kettle

Add 10L of bottled water to kettle

Add malt extract to kettle slowly while stirring

Bring volume in kettle to 25L with water

Attach thermometer to kettle

Boiling

Switch on kettle

Weigh hops while waiting for boil

Bring to a boil

Watch out for boilover in the first 10 mins

Once a rolling vigorous boil is reached, add hops loose

Continue boil for 60 mins (sanitise equipment and set up chiller now)

Add whirlfloc tablet 15 mins from end of boil

Cooling

Connect hose to tap

Connect hose to each end of chiller with hose repair attachment

Run short hose length from output to drain

Immerse chiller in wort five mins from end of boil

When boil complete, turn on tap

Swirl chiller every few mins to ensure wort is circulating well

Chill until wort reaches 20 degrees

Remove thermometer (so we can use for O.G. temp recording)

Transfer to fermenter & pitch yeast

During boil, sanitise using VWP:

Fermenter & lid

Airlock

Scissors

Fermenter tap

Transfer wort to fermenter through tap

Take sample for Original Gravity reading and allow to settle

Pitch yeast

Seal fermenter

Move fermenter to final position

Fill airlock and add to fermenter

O.G. Reading: 1.044 @ 20 degrees C [this thankfully matches the anticipated value!]

Clean kettle and equipment